WELD ANALYSIS SYSTEM

Product Details:

- Capacity (Person) Up to 10 users

- Interface Type Touchscreen LCD, USB, Ethernet

- Compatible System Windows and Linux OS

- Support System PC Software and Cloud Integration

- Language Support English

- Usage Weld quality monitoring, real-time analysis

- Security Features User authentication, data encryption

20000 INR/Box

X

WELD ANALYSIS SYSTEM Price And Quantity

- 20000.00 - 50000.00 INR/Box

- 1 , , Box

- 20000 INR/Box

WELD ANALYSIS SYSTEM Product Specifications

- Windows and Linux OS

- Up to 10 users

- Touchscreen LCD, USB, Ethernet

- Automated weld analysis equipment

- English

- Weld quality monitoring, real-time analysis

- PC Software and Cloud Integration

- Industrial welding data analysis and process improvement

- User authentication, data encryption

WELD ANALYSIS SYSTEM Trade Information

- 1 , , Box Per Day

- 1 Week

Product Description

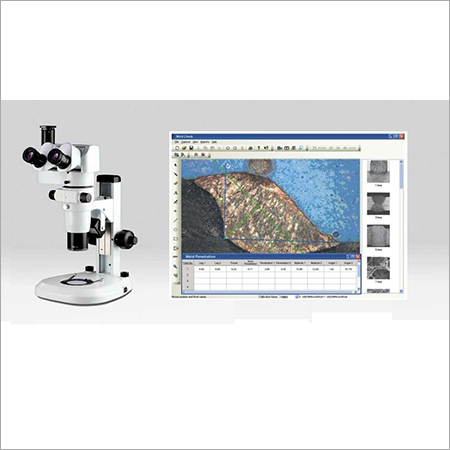

SPECIFICATIONS

EYEPIECE

- Wide field Eyepieces 10X (Paired) FOV 22mm

OBJECTIVES

- Zoom 0.7X to 5x with magnification ratio of 6:1

MECHANICAL BODY

- Lateral zoom control movement.

- Reflected and transmitted light system with 12V-10W halogen tungsten lamp.

- The system regulated with transformer has intensity control knob.

- On/off switch provides flexibility to use either both light or any of them.

- Clip for holding specimen.

- Base size is 260mm X 290mm.

MAGNIFICATION RANGE

- 7X - 50X

WORKING DISTANCE

- 98mm

High-Performance Data Acquisition

The system captures up to 10,000 samples per second, enabling precise monitoring and analysis of welding parameters. Users can connect multiple sensors to measure temperature, current, and voltage, providing comprehensive data for process optimization.

Intuitive Touchscreen Operation

Navigate through settings and analysis tools with a responsive, 7-inch HD touchscreen display. The interface streamlines operation, enhancing workflow efficiency and user experience in demanding industrial environments.

Flexible Storage and Connectivity

Equipped with a 64GB internal SSD, expandable via USB, the device ensures secure data retention. Wi-Fi, Bluetooth, and Ethernet options facilitate seamless integration with external devices and cloud platforms for remote access and data sharing.

Comprehensive Reporting & Security

Customize analytical reports in PDF or Excel formats. Security features such as user authentication and data encryption safeguard sensitive production information, ensuring compliance with industry standards.

FAQs of WELD ANALYSIS SYSTEM:

Q: How does the WELD ANALYSIS SYSTEM improve weld quality monitoring?

A: The system delivers real-time analysis by acquiring welding data through compatible sensors at up to 10,000 samples per second. It helps detect irregularities quickly, enabling prompt process adjustments and enhancing overall weld integrity.Q: What sensors can be used with this system and for which measurements?

A: This equipment works seamlessly with temperature, current, and voltage sensors, allowing users to monitor critical welding parameters and tailor data collection to specific process requirements.Q: When is it beneficial to generate customizable PDF or Excel reports?

A: Customizable report generation is useful after each welding session or batch, enabling documentation, traceability, and sharing of results with stakeholders for continuous process improvement or quality auditing.Q: Where can the WELD ANALYSIS SYSTEM be deployed?

A: The system is ideal for industrial settings, fabrication plants, research labs, and any environment where consistent weld quality and process optimization are mandatory.Q: What is the process for setting up and using the system?

A: Setup involves connecting sensors, configuring user access, and choosing preferred storage options. Users operate the device via touchscreen, store and analyze data, and generate reports through the integrated software, with support for cloud integration.Q: How do the security features benefit users and data safety?

A: User authentication and data encryption prevent unauthorized access and ensure sensitive welding data remains confidential and protected during transmission and storage.Q: Which operating systems are compatible with the WELD ANALYSIS SYSTEM?

A: The system supports both Windows and Linux OS, enabling integration with existing infrastructure and flexibility for various IT environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Weld Penetration Inspection System' category

|

METKORP EQUIPMENTS PVT. LTD

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |